Transforming Key Industries with Handheld Inkjet Printer Technology

Handheld inkjet printers are warmly welcomed by various industries and have significantly reshaped operational dynamics across several key industries, primarily food and beverage, manufacturing, logistics, and packaging. Historically, these sectors faced considerable challenges in printing, labeling, and marking, grappling with inefficiencies that stifled productivity and adaptability. The introduction of handheld inkjet printers has not only addressed these challenges but also fundamentally altered workflows, enhancing efficiency and flexibility. In this article, we delve into the transformative impact of handheld inkjet printers on these four key industries, highlighting their applications, challenges, and the innovative solutions they provide.

1. Food and Beverage Industry

Overview: The food and beverage industry's stringent labeling requirements, necessitating accurate and up-to-date information on production and expiry dates, batch numbers, and nutritional content, are vital for consumer safety and compliance with regulatory standards.

Challenge Before Handheld Printers: Traditionally, workers in the food industry had to manually label products, a process that was not only time-consuming but also resource-intensive. This manual approach to labeling was prone to errors and inefficiencies, significantly impacting productivity and operational costs.

Transformation with Handheld Printers: The introduction of handheld inkjet printers like the Bentsai B2 printer gun has dramatically improved labeling processes in the food industry. These printers offer a photoelectric print mode, which, when combined with a sensor and conveyor belt, enables automatic printing on various product containers regardless of their shape—be it water bottles, pouch bags, cans or other types. This capability ensures fast, clear, and precise inkjet printing directly on the surface of food product containers.

The transition to handheld label printer in the food industry exemplifies how these devices enhance operational efficiency, improve compliance, and adapt to diverse packaging needs. This shift not only streamlines the labeling process but also supports the industry's ability to meet high safety standards and respond to market demands swiftly.

2. Packaging Industry

Overview and Challenge: The packaging sector emphasizes the need for customized printing solutions for logos, specifications, and branding purposes. Businesses often face challenges with minimum order quantities (MOQs) and the high costs associated with traditional printing equipment for packaging boxes, which was not cost-effective for small-scale operations or those requiring frequent design changes. The MOQ for orders further compounded the issue, limiting flexibility and increasing costs.

After the Handheld Printer: Handheld inkjet printers have revolutionized the packaging industry by offering a more cost-effective and flexible solution. These printers allow for easy customization and on-demand printing of packaging materials, eliminating the need for large upfront investments and reducing the constraints imposed by MOQs. Businesses can now efficiently manage small batch runs and personalized packaging, significantly reducing waste and enhancing market responsiveness. Moreover, with the diverse material compatibility of handheld printers, any packaging materials can be printed without issues.

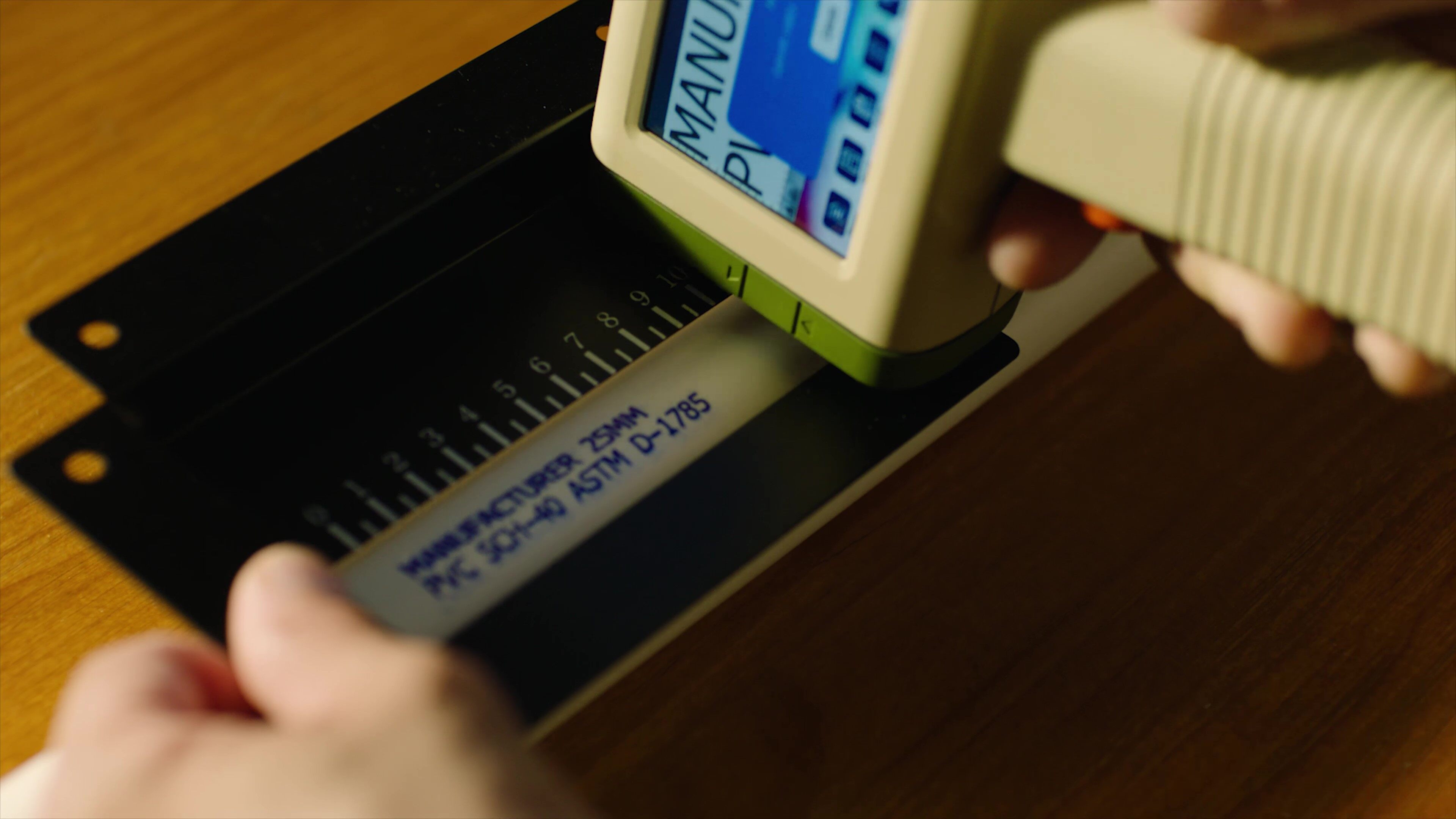

3. Manufacturing Industry

Overview: Manufacturing relies on precise labeling for asset tracking, inventory management, and quality control, necessitating clear and durable markings on a variety of materials.

Before the Handheld Printer: The use of stationary printers created bottlenecks and increased the risk of errors, as items had to be transported to specific locations for labeling, disrupting the workflow.

After the Handheld Printer: Handheld printer enables immediate on-site labeling, eliminating bottlenecks and reducing errors. This change has streamlined production processes and improved the accuracy of inventory tracking and product quality.

4. Logistics Industry

Overview: Logistics operations require the efficient management of shipments, with accurate labeling for tracking, routing, and delivery information being paramount.

Before the Handheld Printer: Fixed printing stations could not accommodate the fast-paced and variable nature of logistics, leading to potential inefficiencies and delays in shipment processing.

After the Handheld Printer: The adoption of handheld inkjet printers has brought flexibility to logistics, allowing for the on-demand printing of shipping labels and documents. This improvement has optimized package handling, enhanced supply chain efficiency, and ensured more reliable delivery processes.

The adoption of handheld inkjet printers across the food, manufacturing, logistics, and packaging industries underscores a broader shift towards technologies that offer flexibility, efficiency, and precision. These devices are not just tools but transformative agents, enabling businesses to meet the challenges of modern operations and market demands. As industries continue to evolve, the role of handheld printers in driving innovation and improving operational capabilities will undoubtedly expand, reflecting their critical importance in the industrial landscape.

If you're in need of a reliable portable handjet printer, don't hesitate to contact Bentsai as we offer the most top quality thermal inkjet printing technologies with over 100 patents and 2 decades of industry experience.

Ask Question

No questions and answers