How to Print Date Code on Plastic?

Printing dates on plastic items, such as expiration dates or manufacturing dates, is a common practice in various industries. The method chosen can depend on the type of plastic, the production volume, and the required durability of the marking. In this guide, we will introduce some of the most commonly used techniques and printer types, and then compare their functionality, applications, pros and cons one by one.

What Type of Printers and Techniques Can Print on Plastic Materials?

1. Continuous Inkjet Printers (CIJ)

(Image Credit: Videojet)

- Functionality: CIJ printers propel ink droplets onto a substrate through a high-speed, continuous stream. The droplets are charged and then directed onto the surface to form characters and numbers.

- Ideal for: High-speed production environments. They are versatile for marking on almost any surface, including various types of plastics.

- Pros: Fast printing speeds; capable of printing on curved, uneven, or textured surfaces; easy to change messages.

- Cons: Consumable costs (ink and solvents) can be high; requires regular maintenance to ensure optimal performance.

2. Thermal Inkjet Printers (TIJ)

- Functionality: TIJ printers use cartridges similar to those in desktop printers, where heat is used to expel ink droplets onto the surface to be printed on.

- Ideal for: Applications requiring high print quality and lower volume production. Suitable for both porous and non-porous surfaces.

- Pros: High-resolution prints; lower maintenance compared to CIJ; easier to operate.

- Cons: Slower print speeds than CIJ; higher cost per print due to cartridge use.

Looking for a reliable thermal inkjet printer? You must not miss Bentsai – an expert in manufacturing portable handheld inkjet printer using thermal inkjet technology. Bentsai handheld printer guns use solvent based ink that dries in seconds and can be applied to plastic materials directly without pre-coating. Whether the plastic surface is flat or round, even or uneven, Bentsai handheld inkjet printers can handled it all. Print quality is supreme and last very long. The best part? These portable printers do not need huge space and can be carried around to finish the printing while on the go!

3. Laser Marking Machines

(Image Credit: Linxuanlaser)

- Functionality: These machines use lasers to etch or mark the surface of the plastic without contact. The laser beam modifies the surface of the material to create a permanent mark.

- Ideal for: Permanent, high-quality, and precise marking requirements. Works well with various types of plastics.

- Pros: Very durable marks; resistant to fading, chemicals, and abrasion; no consumables required; minimal maintenance.

- Cons: Higher initial investment; certain types of plastics may require specific types of lasers for effective marking; the marking speed can be slower compared to some inkjet solutions.

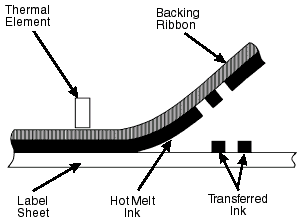

4. Thermal Transfer Overprinters (TTO)

(Image Credit: Wikipedia)

- Functionality: TTO printers use a thermal printhead to melt a wax or resin-based ink from a ribbon onto the substrate to create a high-resolution image.

- Ideal for: Flexible packaging films, labels, and other plastic materials where high-quality and durable prints are required.

- Pros: Durable prints; capable of printing both text and barcodes; good for high-resolution requirements.

- Cons: Requires the use of a ribbon, adding to the consumable costs. may not be as fast as direct inkjet printing.

5. Drop on Demand (DOD) Inkjet Printers

- Functionality: DOD printers generate ink droplets only when required for printing, unlike CIJ printers that continuously eject ink. They can be further divided into piezoelectric and valve-jet printers.

- Ideal for: Applications requiring larger prints or where the print frequency is lower. Suitable for a wide range of packaging applications.

- Pros: Efficient use of ink; capable of printing larger characters; lower maintenance than CIJ.

- Cons: May not be as suitable for high-speed or very high-resolution requirements compared to other inkjet technologies.

6. Hot Stamp Printing

- Overview: Hot stamp printing, also known as foil stamping, uses heat and pressure to transfer pre-dried ink or foils to the surface of a product. This method involves a heated die that presses the foil against the substrate, leaving behind the desired mark.

- Unique Characteristics: It's particularly well-suited for high-quality, durable markings on plastic parts. The process can achieve metallic finishes and is often used for decorative purposes in addition to functional date coding.

- Application Areas: Commonly used for marking high-value items or where a premium look is required, such as cosmetic packaging, automotive parts, and electronic devices.

- Comparison: Unlike inkjet or laser printers, hot stamp printing does not require inks or solvents during operation, making it a different category of printing technology. It's more mechanical in nature and less versatile for changing markings quickly but offers durability and a unique aesthetic appeal.

- Pros: Provides a durable mark; can be cost-effective for small to medium volumes.

- Cons: Not as flexible for changing information frequently; slower compared to inkjet printing.

7. Pad Printing

(Image Credit: Sunrise-metal)

- Overview: Pad printing involves transferring ink from an etched plate onto the product using a soft silicone pad. This method is highly adaptable and can print on uneven or complex surfaces.

- Unique Characteristics: Pad printing is capable of delivering high-quality images on irregular shapes, making it ideal for products that are difficult to mark with other methods. It can use a variety of inks to adhere to different types of plastics.

- Application Areas: Widely used in the medical device industry, automotive components, toys, and electronics for printing logos, instructions, and date codes on parts with challenging geometries.

- Comparison: This method stands apart from digital printing technologies like inkjet or laser due to its mechanical nature and the direct transfer of ink via a pad. It offers versatility in substrate shape and texture but is generally suited for lower-volume runs or specific applications where digital methods may not be feasible.

- Pros: Very versatile for different shapes and textures; good for small to medium-sized batches.

- Cons: Each color requires a separate print cycle, which can slow down production for multi-colored prints.

Conclusion: Choosing the Right Method

Each printer type and printing technique has its unique advantages and considerations, making them suitable for different applications within the realm of date coding on plastic products. The choice between the date code printer often comes down to various factors including the specific requirements for durability, production speed, cost considerations, and the physical characteristics of the plastic product being marked. It's also important to consider the environmental conditions the product will be exposed to, as this can affect the longevity and visibility of the print.

Future Prediction

Looking ahead, technological advancements promise even greater efficiency and sustainability. Innovations like eco-friendly inks and energy-saving equipment highlight the industry's shift towards practices that prioritize the planet's health alongside consumer demands.

As we navigate these choices, the emphasis on selecting environmentally conscious printing solutions becomes paramount. Whether aiming to enhance production efficiency or reduce ecological footprints, there's an optimal printing solution for every need. Embracing these technologies not only meets today's requirements but also aligns with a sustainable future.

Ask Question

No questions and answers