Simplified Marking Solutions: Ultimate Guide to Handheld Inkjet Printers

Conventional labels involve multiple steps, consumables, and storage costs, while errors often mean reprinting or relabeling.

In contrast, handheld inkjet printers enable direct, on-demand marking—simplifying workflows and adapting to modern production needs.

Therefore, businesses are shifting from traditional labeling to smart marking as speed, flexibility, and sustainability become critical.

Why Businesses Are Ditching Traditional Labels?

1. Efficiency

- ● Labels require printing, peeling, and applying—each step adds time

- ● Errors mean wasted labels and rework

2. Cost Reduction & Environmental Protection

- ● Direct-to-object (DTO) printing eliminates label inventory

- ● Reduces backing paper, plastic waste, and storage space

3. Traceability Requirements

- ● On-demand printing supports variable data such as dates, lot codes, and serial numbers

- ● Easier compliance with industry and regulatory standards

Traditional Labeling vs. Handheld Inkjet Marking

Before choosing a marking solution, it is important to understand how traditional labeling methods compare with handheld inkjet marking in real-world applications.

The comparison below highlights the key factors businesses should evaluate when deciding whether to continue using labels or transition to direct inkjet marking.

| Factor | Traditional Labels | Handheld Inkjet Marking |

| Cost per Mark | Ongoing label + labor cost | Ink-only, lower long-term cost |

| Surface Applicability | Limited by label material | Unlimited materials |

| Workflow Speed | Multi-step | One-step, instant |

| Durability | Can peel or fade | Ink bonds directly to surface |

| Inventory Management | Requires label stock | No label inventory |

| Environmental Impact | Higher waste | Reduced consumables |

Benefits of Handheld Inkjet Printer

Handheld inkjet printers are designed to meet both industrial and personal marking needs by combining portability with powerful printing capabilities. Their benefits extend across different user groups—from businesses seeking productivity gains to individuals looking for creative and practical printing solutions:

For Businesses

- Faster marking directly on products or packaging

- Flexible variable data printing (dates, barcodes, QR codes)

- Reduced consumables and operational costs

- Easy deployment across multiple workstations

For Individuals

- Portable and easy to use

- Ideal for DIY labeling, crafts, and personalization

- No need for bulky equipment

Tech Specs

- Technology Type: Thermal Inkjet (TIJ)

- Print Resolution: Up to 300 DPI

- Ink Types: Water-based & solvent-based

- Print Height: Small to large characters (model-dependent)

- Battery Life: Several hours to full-shift operation

- Connection Method: Touchscreen, USB, Bluetooth, Wi-Fi

Practical Application Cases

1. Logistics & Warehousing

- Application: Carton codes, location marks, barcodes

- Benefit: Faster picking, packing, and traceability

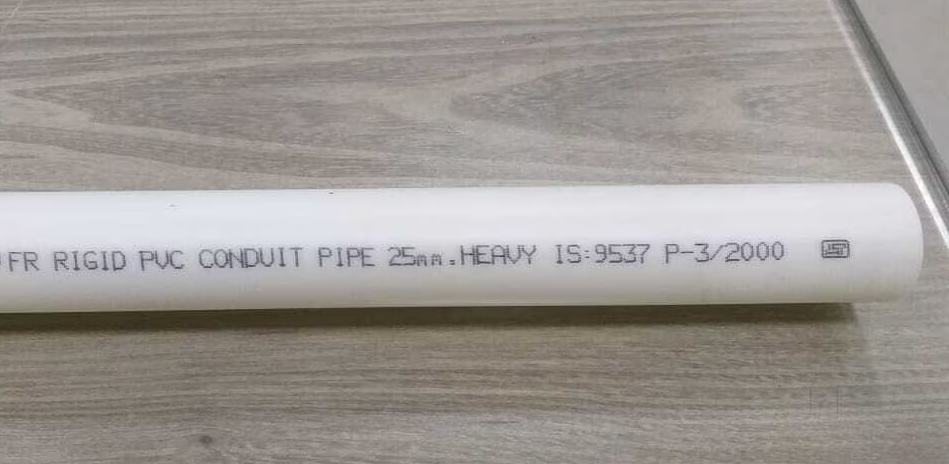

2. Construction & Heavy Industry

- Application: Pipes, cables, concrete blocks

- Benefit: Durable, large-format markings without labels

3. Retail & Food Service

- Application: Date codes, batch numbers, shelf labels

- Benefit: Compliance and quick updates without relabeling

Frequently Asked Questions

● Question: How much money can a handheld inkjet printer save compared to labels?

○ Answer: Savings come from eliminating label materials, storage, and rework—often significant over time.

● Question: Can I automate my workflow using handheld inkjet printers?

○ Answer: Yes. Some models support photoelectric sensors and variable data printing for semi-automation.

● Question: Is the ink permanent on glass and plastic?

○ Answer: With the correct ink type, prints are durable and resistant to smudging or moisture.

In Conclusion

Handheld inkjet printers replace complex labeling with a faster, cleaner, and more flexible marking approach. Whether for industrial production or everyday use, they reduce costs, improve efficiency, and support modern traceability needs.

Ask Question

No questions and answers