Unveiling the Science of Date Coding: Techniques for Precision

Date coding, also known as date marking or date printing, is a process of adding a date or date-related information to a product or its packaging. This information is crucial for various industries, especially those involved in food and beverage manufacturing, pharmaceuticals, cosmetics, and other sectors where product freshness, safety, and quality control are essential. In this article, we will explore the significance of date coding, various date code types, and the methods that help streamline the process.

Why is date coding important?

Date coding primarily serves three key purposes:

- Quality Assurance: Date codes, such as "Best Before" and "Use By" dates, help consumers make informed choices by indicating the product's freshness and quality.

- Inventory Management: Manufacturers and retailers use date coding to monitor product shelf life, enabling efficient stock rotation and reduced waste.

- Traceability: In the event of a product recall or quality issue, date codes, and lot numbers enable swift identification and removal of affected items from the market.

How many types of date codes are there?

Before exploring methods of date coding, it's essential to understand the various types of date codes commonly used:

- Manufacturing Date: This indicates when the product was made, allowing for better inventory control and quality assurance.

- Expiry Date: The expiry date, often called the "use by" or "best before" date, informs consumers about the date until which the product is expected to remain safe and of good quality.

- Lot or Batch Number: This is a unique code for each production batch, which is useful for tracking and quality control.

How to print date codes?

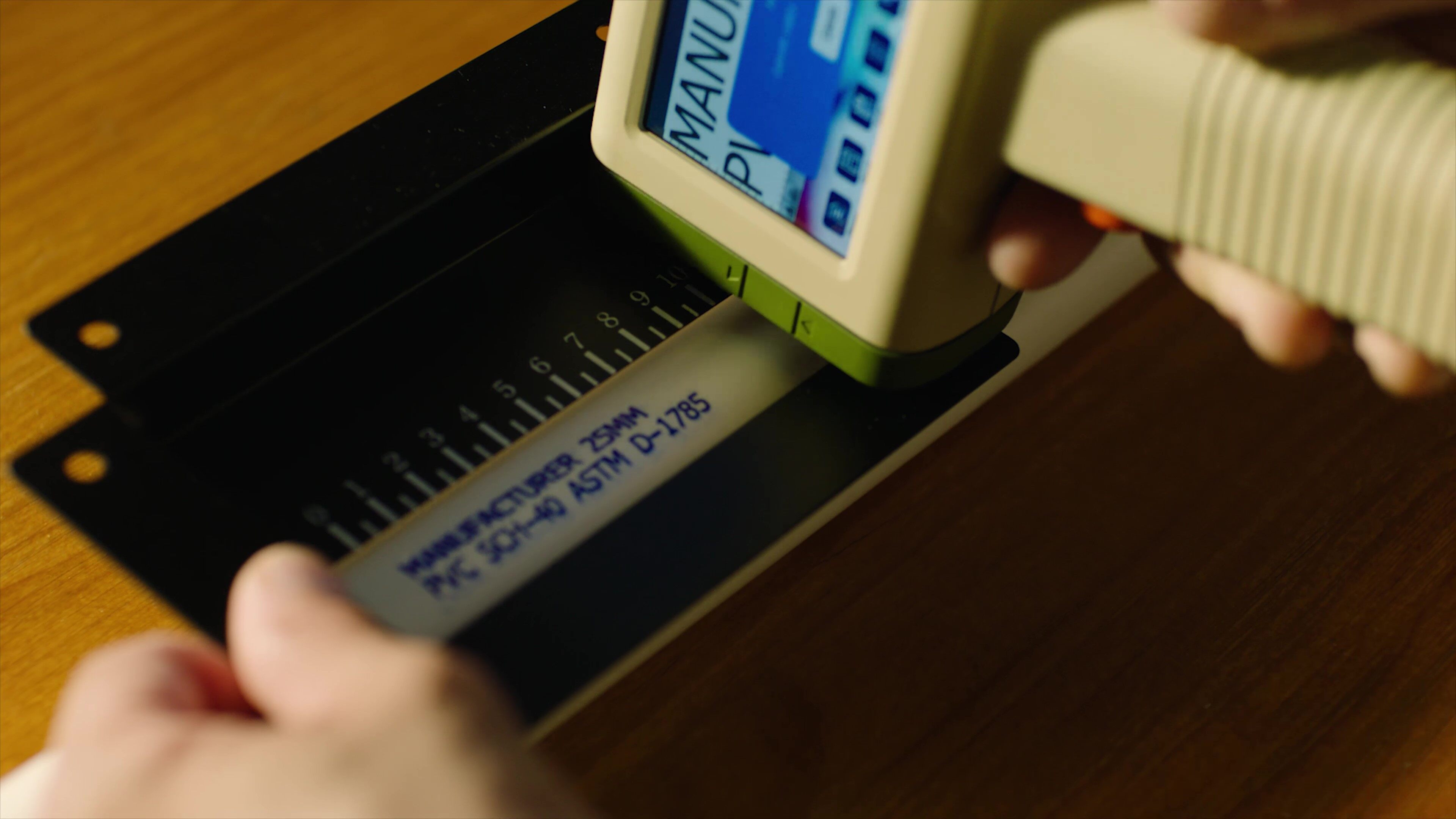

- Inkjet Printing: Inkjet printers use liquid ink to create date codes on product packaging. This method is versatile and can be used for various substrates that are commonly used in food, beverage, cosmetics, skincare, pharmaceutical industries. When it comes to inkjet printing, here at BENTSAI, we offer a range of small character handheld inkjet printers that are perfect for printing dates, batch codes, and serial numbers on various surfaces. With Bentsai's handheld printers, you can ensure precise and consistent date coding for all your products and packaging needs.

- Laser Marking: Laser marking is a non-contact method that uses laser technology to create permanent date codes on products and packaging.

- Thermal Printing: Thermal printers use heat to create date codes on labels or packaging. It's commonly used in barcode and label printers.

- Hot Stamping: Hot stamping uses heat and a foil ribbon to transfer date codes onto packaging materials. It's often used for high-quality printing on labels.

Incorporating the right date coding method into your product management process depends on your specific requirements, the materials you work with, and the desired outcome. Technical considerations play a crucial role in ensuring that your date codes are accurate, durable, and compliant with industry standards.

Additional Considerations

In addition to choosing the right date coding method, factors like local regulations, industry standards, and product-specific requirements should be considered. Properly executed date coding not only ensures product quality, safety, regulatory compliance but also enhances consumer trust in your brand.

In Conclusion

In conclusion, date coding is a critical aspect of product and supply chain management that should not be overlooked. Choosing the right date code type and method can significantly impact product quality, safety, and overall efficiency.

For precise and reliable date coding, explore the versatile range of Bentsai handheld inkjet printers and elevate your product management practices to the next level.

Ask Question

No questions and answers